Introduction

In the realm of precision cutting, waterjet technology stands as a beacon of innovation, offering unparalleled accuracy and versatility across various industries. Leading this technological landscape are two prominent players: OMAX and WARDJet. In our detailed analysis, we dive deep into a head-to-head comparison between the OMAX 2626 and the WARDJet A-Series, evaluating them on key performance metrics, usability, affordability, and overall value. By the end of this blog, not only will you understand the intricacies of these powerful machines, but you’ll also appreciate why OMAX remains a favorite among industry professionals.

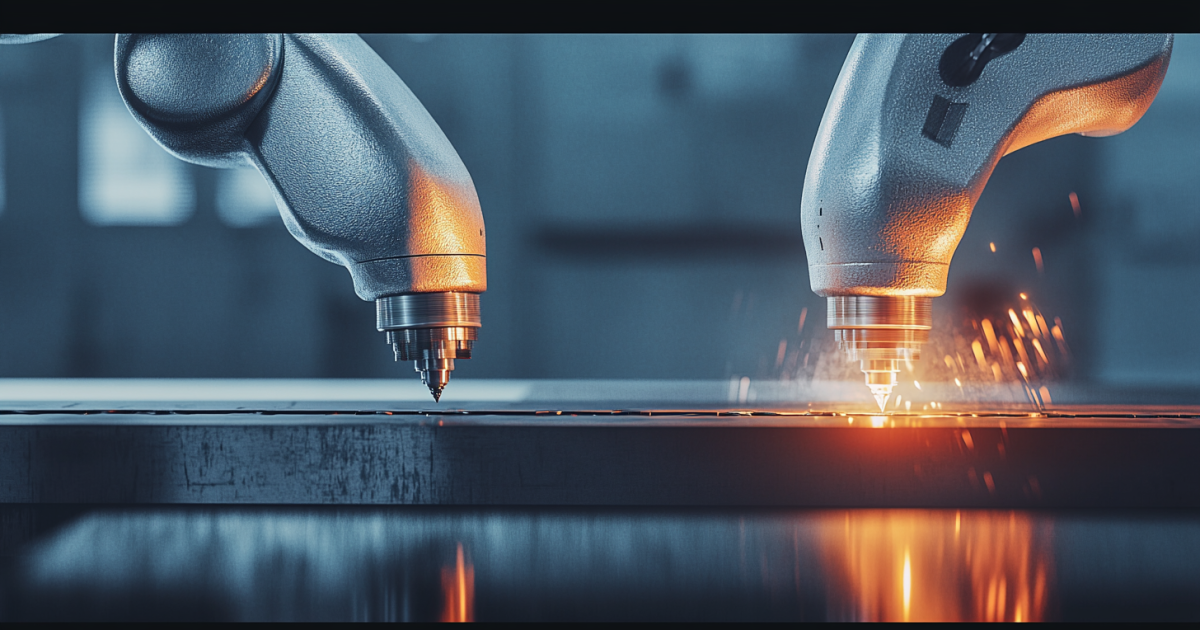

Performance and Accuracy

Cutting Speed and Efficiency

One of the foremost criteria in assessing waterjet cutting machines is their cutting speed and efficiency. The OMAX 2626 stands out with its proprietary Intelli-MAX® software, which optimizes cutting paths and improves overall machine efficiency. This translates to faster job completions without compromising precision, crucial for industries with tight deadlines.

In contrast, the WARDJet A-Series offers competitive cutting speeds but lacks the advanced software optimization found in the OMAX models. Users of the WARDJet A-Series may encounter increased setup times and manual adjustments to achieve similar levels of precision, ultimately impacting productivity.

Precision and Finish Quality

When it comes to waterjet cutting, precision is paramount. The OMAX 2626, equipped with the advanced EnduroMAX® pump, ensures consistent cutting pressure, resulting in smooth and accurate cuts every time. The machine’s dual-drive system further enhances stability, significantly reducing the chances of material deviation during cutting.

The WARDJet A-Series, while capable of delivering precise cuts, often requires additional calibration and maintenance to maintain its accuracy over time. This can be a notable drawback for operators who prioritize consistency and minimal downtime.

User Interface and Ease of Use

Software and Controls

An intuitive user interface can dramatically impact the efficiency and learning curve of operating a waterjet cutting machine. The OMAX 2626 boasts a user-friendly interface through its Intelli-MAX® software suite, offering a range of functionalities from beginner to advanced levels. Users can easily customize settings, simulate cutting paths, and manage complex projects with minimal effort.

WARDJet’s A-Series, although equipped with functional software, tends to be more complex and less intuitive for new users. The learning curve is steeper, and operators might require more extensive training to leverage the machine’s full potential, which can be a hindrance for businesses looking to quickly integrate new technology into their workflow.

Maintenance and Operational Overheads

Ease of maintenance plays a critical role in the overall ownership experience of waterjet cutting machines. OMAX 2626 is designed with fewer consumable parts and boasts an efficient maintenance schedule, ensuring minimal operational downtime. The accessible design allows for straightforward, quick repairs and adjustments, further enhancing productivity.

Conversely, the WARDJet A-Series, while robust in build, tends to demand more frequent maintenance checks and part replacements. This can result in higher long-term costs and unexpected interruptions, potentially affecting project timelines and operational budgets.

Affordability and ROI

Initial Investment

The initial cost of acquiring a waterjet cutting machine is a significant factor for many businesses. The OMAX 2626, known for its high-quality construction and advanced features, justifies its price tag with long-term reliability and lower operational costs. The competitive edge provided by high cutting speeds and superior accuracy contributes to a faster return on investment (ROI).

WARDJet’s A-Series might appeal to businesses with limited initial budgets, presenting a lower upfront cost. However, the potential for increased maintenance and calibration expenses should be factored into the total cost of ownership when considering ROI.

Operational Costs and Long-term Value

When evaluating waterjet machines for long-term value, operational costs are as critical as purchase price. The OMAX 2626’s efficient use of consumables, energy savings, and minimal downtime contribute significantly to reducing overall costs. Additionally, the machine’s ability to handle a wide range of materials with ease adds to its versatility and overall value proposition.

While the WARDJet A-Series offers reasonable operating costs initially, the long-term expenses associated with frequent maintenance and part replacements can erode the initial savings. Businesses must weigh these factors carefully to ensure they are making a cost-effective investment.

Customer Support and Community

Access to Support and Resources

Reliable customer support can greatly affect the user experience and overall satisfaction with a waterjet cutting machine. OMAX is renowned for its exceptional customer service, offering extensive resources, quick response times, and a knowledgeable support team. Their online community and training programs further enhance user experience, providing continuous learning opportunities and troubleshooting assistance.

WARDJet offers commendable customer support, but it may not match the comprehensive services and resources provided by OMAX. For users requiring frequent assistance or advanced training, this could be a significant differentiator.

User Community and Feedback

The strength of user communities can also play a vital role in the decision-making process. OMAX has cultivated a robust community of users who actively share insights, solutions, and innovations. This collaborative environment fosters continuous improvement and empowers users to maximize their machine’s capabilities.

While WARDJet also has a supportive user base, it tends to be smaller and less active compared to OMAX. This can limit the exchange of ideas and solutions, potentially impacting the user experience for those relying heavily on community-driven support.

Conclusion

In the comprehensive comparison between the OMAX 2626 and the WARDJet A-Series, it becomes evident that while both machines have their merits, the OMAX 2626 consistently outperforms in critical areas such as precision, ease of use, maintenance, and long-term value. The differential advantages of the OMAX 2626, including its advanced software, superior customer support, and lower operational costs, make it a compelling choice for businesses aiming to integrate high-performance waterjet cutting technology.

As always, the ultimate selection should align with specific operational needs, budget considerations, and long-term business goals. However, with its proven track record and user-centric design, the OMAX 2626 is well-positioned to remain a leader in the waterjet cutting industry.