Section 1: Introduction to Waterjet Cutting Machines

Waterjet cutting machines have revolutionized the manufacturing industry with their precision and versatility. Among the top contenders in this field are the OMAX 2626 and the Jet Edge EDGE X-5. Both machines are renowned for their high performance and innovative technologies, making them popular choices for a range of applications. In this post, we will delve into the detailed comparison of these two machines to understand their strengths, weaknesses, and overall value.

Section 2: Design and Build Quality

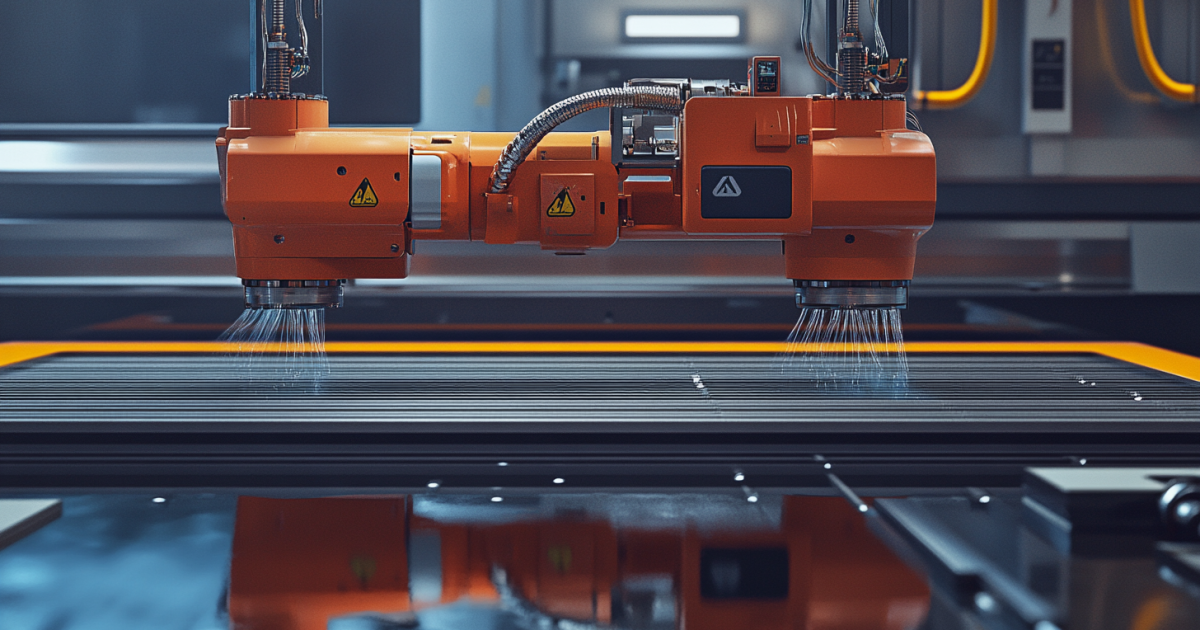

OMAX 2626: Robustness and Reliability

The OMAX 2626 is known for its robust build and reliable performance. Constructed with a rigid, precision-engineered frame, this machine promises stability and durability even in the most demanding industrial environments. The materials used in its construction are of the highest quality, ensuring that the machine can withstand high pressures and deliver consistent results over time.

Another significant advantage of the OMAX 2626 is its compact design, which allows it to fit into smaller workshops without compromising on cutting capabilities. The user-friendly interface and intuitive controls further enhance its appeal, making it accessible to operators with varying levels of experience.

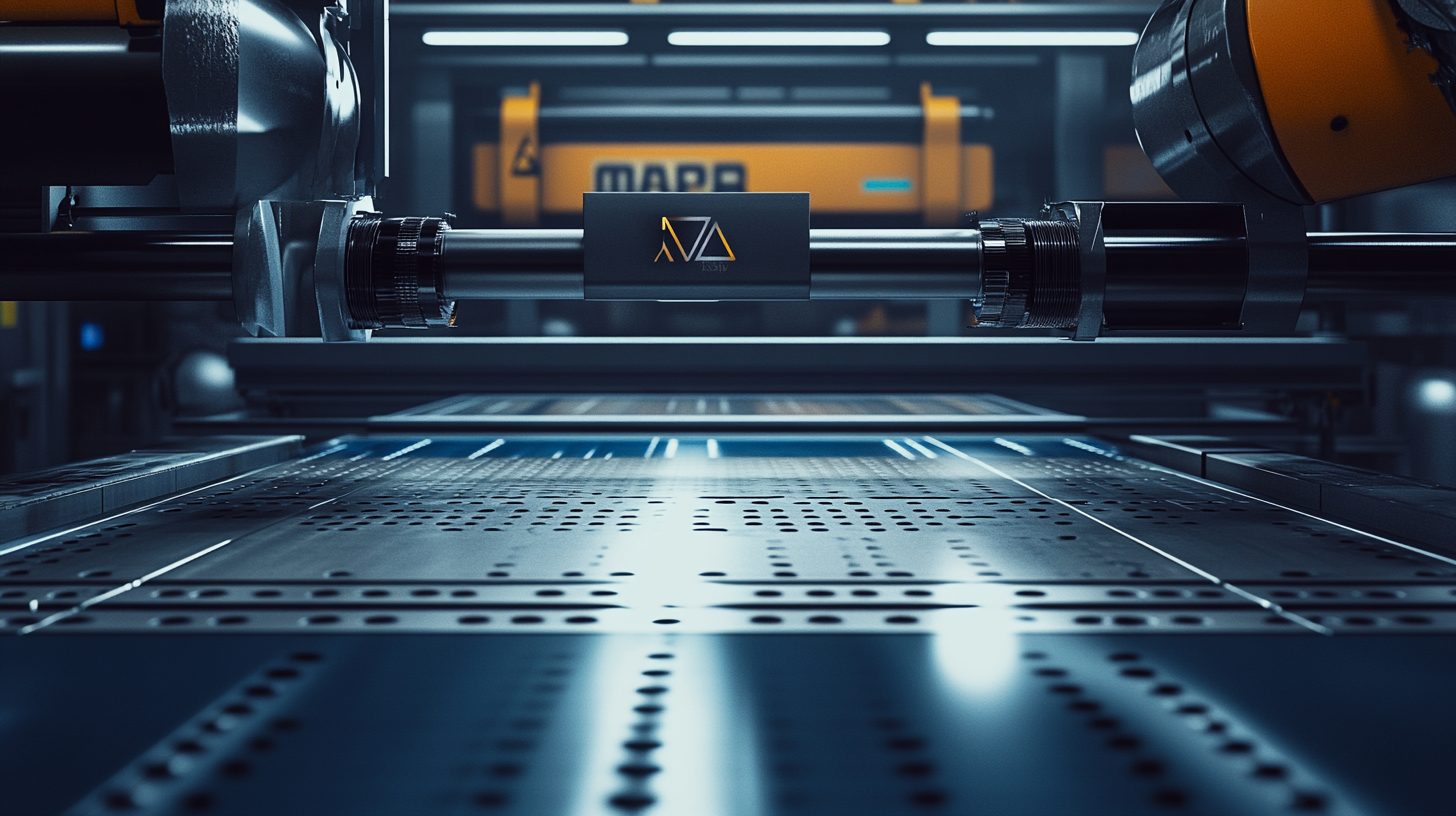

Jet Edge EDGE X-5: Advanced Engineering

The Jet Edge EDGE X-5 offers an engineering marvel with its state-of-the-art frame and advanced design features. Its heavy-duty construction ensures minimal vibration and maximum accuracy, which is crucial for precise cutting applications. The machine’s advanced motion system allows for complex geometries and tight tolerances, making it suitable for high-precision tasks.

While the Jet Edge EDGE X-5 is slightly larger in footprint compared to the OMAX 2626, it offers a robust structure that emphasizes high performance. Its modular design allows for future upgrades, catering to the evolving needs of the industry.

Section 3: Performance and Cutting Capabilities

OMAX 2626: Superior Waterjet Cutting

Performance is where the OMAX 2626 truly shines. Equipped with OMAX’s proprietary cutting technology, it delivers precise cuts with minimal waste. The machine’s ability to cut a wide range of materials, including metals, composites, glass, and ceramics, makes it highly versatile. Its unique Intelli-MAX Software Suite enhances cutting efficiency and accuracy through its advanced algorithms and easy-to-use interface.

Moreover, the OMAX 2626’s direct drive pump ensures consistent pressure, reducing maintenance requirements and downtime. The fast setup and cutting speeds make it an ideal choice for high-volume production environments where time is of the essence.

Jet Edge EDGE X-5: High Precision Performance

The Jet Edge EDGE X-5 is engineered for precision cutting. Its precision cutting head can handle the most intricate designs and tight tolerances, making it suitable for applications that demand utmost accuracy. The EDGE X-5 excels in cutting thick materials, with its powerful pump delivering high pressure to tackle tough cutting jobs.

In terms of performance, the Jet Edge EDGE X-5 offers solid performance metrics, though it may require slightly more maintenance than the OMAX 2626 due to its intricate design. The machine’s versatility is evident in its ability to switch between abrasive and pure waterjet cutting, offering flexibility for varied cutting needs.

Section 4: Software and Usability

OMAX 2626: User-Centric Software

One of the standout features of the OMAX 2626 is its Intelli-MAX Software Suite, which is designed with the user in mind. The intuitive interface and step-by-step guides make it easy for operators to create and execute cutting plans with minimal training. The software’s advanced nesting capabilities optimize material usage, reducing wastage and operational costs.

Additionally, the real-time monitoring and diagnostic tools provided by the software help in ensuring the machine runs smoothly, identifying potential issues before they lead to downtime. The integration of smart technology into the OMAX 2626 positions it as a leader in the realm of user-friendly waterjet cutting machines.

Jet Edge EDGE X-5: Advanced Controls

The Jet Edge EDGE X-5 also boasts advanced control systems designed for high-precision tasks. Its software allows for detailed programmability and customization, giving users the ability to fine-tune their operations. However, the software may present a learning curve for new users, requiring more initial training compared to the OMAX 2626.

The machine’s control system is highly sophisticated, making it particularly suitable for experienced operators who appreciate the level of customization and control it offers. While this complexity can be a boon for specific applications, it may not be as user-friendly as the OMAX offering for general use.

Section 5: Maintenance and Operational Costs

OMAX 2626: Low Maintenance Advantage

One of the significant advantages of the OMAX 2626 is its low maintenance requirement. The direct drive pump system is designed to minimize wear and tear, resulting in longer intervals between maintenance sessions. This translates to lower operational costs and higher uptime, which is a crucial factor for any manufacturing setup.

The availability of comprehensive support and easy-to-source parts further reduces the cost and time associated with maintenance. OMAX’s commitment to customer service ensures users have access to the assistance they need to keep their machines running smoothly.

Jet Edge EDGE X-5: High-End Maintenance

The Jet Edge EDGE X-5, while robust and high-performing, tends to require more frequent maintenance due to its complex design. The high-pressure pumps and intricate components may necessitate more regular checks and part replacements. This can lead to higher operational costs over time.

However, Jet Edge offers comprehensive support services and maintenance plans, which can help mitigate these issues. For businesses that prioritize cutting-edge technology and are prepared for the associated maintenance, the EDGE X-5 can still be a worthwhile investment.

Conclusion: Which One Wins?

In the battle between the OMAX 2626 and the Jet Edge EDGE X-5, the choice ultimately comes down to specific operational needs and priorities. The OMAX 2626 stands out for its ease of use, low maintenance, and overall reliability, making it an excellent choice for a wide range of applications. Its user-centric design and advanced software make it accessible for both seasoned operators and newcomers to waterjet cutting technology.

On the other hand, the Jet Edge EDGE X-5 offers unparalleled precision and engineering sophistication. For applications requiring high precision and complex cutting capabilities, it presents a compelling option despite its higher maintenance requirements.

Both machines have their merits, but for businesses looking for a balance of performance, ease of use, and cost-efficiency, the OMAX 2626 edges out as the superior choice. Its robust design, user-friendly software, and low operational costs make it a formidable contender in the waterjet cutting industry.