Introduction to the Laser Cutting Titans

When it comes to the realm of laser cutting, the ByStar Fiber 3015 by Bystronic and the AMADA ENSIS-3015AJ are two machines that stand out. These powerhouses are renowned for their precision, efficiency, and innovative technology. In this ultimate battle, we’ll put these two laser cutting behemoths head-to-head, examining their unique features, performance metrics, technological advancements, ease of use, and potential applications. By diving deep into the specifics, we aim to provide you with a clear picture of which machine suits your manufacturing needs best.

While both machines boast impressive capabilities, each has its own strengths that cater to different manufacturing requirements. As we progress through this detailed comparison, you’ll find insightful observations that highlight how these machines perform in real-world scenarios.

Feature Breakdown: ByStar Fiber 3015 and AMADA ENSIS-3015AJ

Design and Build Quality

The ByStar Fiber 3015 offers a robust design built to withstand the rigors of industrial use. Its solid frame provides stability and reduces vibrations, ensuring precise cuts even at high speeds. The machine’s ergonomic design also makes it user-friendly, allowing operators to work efficiently without unnecessary strain.

In contrast, the AMADA ENSIS-3015AJ is equally industrial-strength with a focus on flexibility and adaptability. AMADA has incorporated a refined structural design to optimize both footprint and functionality. The build quality is top-notch, ensuring durability and long-term performance.

Both designs are commendable, but the ByStar Fiber 3015 edges ahead due to its advanced ergonomic features and slightly more rugged build, offering an edge in environments where machine resilience is critical.

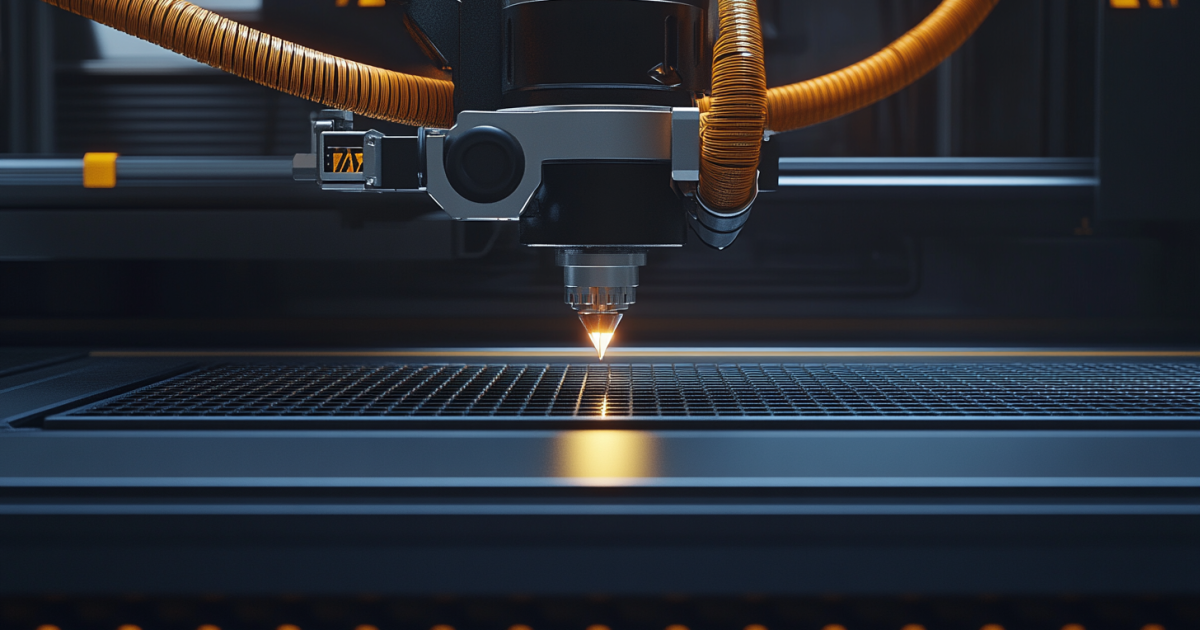

Cutting Edge Technology

Bystronic’s ByStar Fiber 3015 is renowned for integrating high-tech laser cutting technology. It features a precise fiber laser that excels at cutting various materials with minimal post-processing required. Its “BeamShaper” option allows users to adjust the laser beam for consistent quality across different material thicknesses.

The AMADA ENSIS-3015AJ is no slouch when it comes to technological advancements. Its Variable Beam Control technology adjusts the beam’s diameter and focal point in real-time, catering to a diverse range of materials and thicknesses. This ensures that cuts are clean, quick, and efficient.

Both machines showcase incredible technological prowess. However, from a technological standpoint, the ByStar Fiber 3015, with its BeamShaper option, provides more customizable laser cutting, making it slightly more versatile for specialized applications.

Performance and Efficiency

Performance is paramount when selecting a laser cutter. The ByStar Fiber 3015 delivers exceptional speed and accuracy, making it ideal for high-volume production. Its intelligent design minimizes downtime and maximizes throughput, reducing production costs in the process.

The AMADA ENSIS-3015AJ is revered for its efficiency, particularly in power consumption. It delivers excellent performance without compromising on energy usage, making it a greener choice for environmentally conscious manufacturers.

While both machines excel in performance, the ByStar Fiber 3015’s superior speed and operational efficiency make it more suitable for intense production environments where high throughput is essential.

Operational Ease and User Experience

Intuitive Interfaces

Bystronic has always prioritized user experience, which is evident in the ByStar Fiber 3015’s intuitive interface. The touch screen control system is straightforward, reducing the learning curve for new operators. Additionally, the software integrates seamlessly with existing manufacturing systems, enhancing workflow efficiency.

The AMADA ENSIS-3015AJ also offers a user-friendly interface, though it may be slightly more complex compared to Bystronic’s system. While it includes many advanced features, the learning phase can be extended for those unaccustomed to its operations.

Ease of use is a significant factor in operational efficiency, and here, the ByStar Fiber 3015 takes the lead with its more accessible and operator-friendly interface.

Maintenance and Support

Regular maintenance is crucial for the longevity and reliability of laser cutting machines. Bystronic provides exceptional support and maintenance options for the ByStar Fiber 3015, ensuring minimal downtime and consistent performance. Their global support network ensures assistance is never far away.

AMADA equally offers robust support services, with a strong focus on customer satisfaction. Their maintenance protocols are comprehensive and designed to keep the ENSIS-3015AJ running smoothly.

Both brands are commendable in this aspect, but Bystronic’s extensive global support network gives the ByStar Fiber 3015 an edge, especially for businesses operating in multiple locations.

Applications and Versatility

Diverse Material Handling

The ByStar Fiber 3015 shines when it comes to handling diverse materials. From thin sheets of metal to thicker, more challenging substrates, this machine delivers consistent, high-quality cuts. Its adaptability makes it suitable for a broad range of applications, from automotive manufacturing to aerospace components.

The AMADA ENSIS-3015AJ is also versatile, handling various materials with ease. It particularly excels in cutting thinner materials, thanks to its precision beam control technology.

While both machines are versatile, the ByStar Fiber 3015’s broader material compatibility places it ahead, especially for manufacturers requiring a machine that can handle an extensive range of materials.

Specialized Applications

Specialized applications often demand machines capable of maintaining precision under complex requirements. The ByStar Fiber 3015 is designed to excel in such scenarios, providing features like auto nozzle change and additional software options tailored to complex cutting demands.

The AMADA ENSIS-3015AJ, with its advanced beam control, also addresses specialized needs effectively, though it is optimized primarily for tasks involving finer materials.

In specialized applications, the ByStar Fiber 3015’s additional functionalities give it an advantage, providing more tailored solutions to meet diverse and demanding production requirements.

Conclusion: The Ultimate Laser Cutting Champion

As we conclude this ultimate battle between the ByStar Fiber 3015 and the AMADA ENSIS-3015AJ, it’s clear that both machines are exemplary in the world of laser cutting. Each has its unique strengths and caters to different aspects of manufacturing excellence.

The ByStar Fiber 3015 shines with its robust design, advanced technological features, superior performance, and user-friendly operation. Its ability to handle diverse materials and specialized applications makes it a top contender for a broad range of industries.

The AMADA ENSIS-3015AJ, while equally impressive, excels in energy efficiency and precision cutting of thinner materials. It’s an ideal choice for manufacturers focused on power consumption and fine cutting tasks.

In this head-to-head comparison, the ByStar Fiber 3015 emerges as the ultimate laser cutting champion, especially for manufacturers seeking versatility, high throughput, and cutting-edge technology.